.jfif)

ما هو راوتر سي ان سي للاخشاب؟

ما هو جهاز التوجيه الخشبي باستخدام الحاسب الآلي؟

جهاز توجيه الخشب CNC يسمى أيضًا آلة نحت الخشب CNC أو آلة نقش الخشب CNC في صناعة آلة الخشب CNC. يشير إلى قدرة جهاز التوجيه CNC على أداء الحركة حول ثلاثة محاور مختلفة مثل المحور X و Y و Z في نفس الوقت. تم تصميم هذا النوع من موجه الخشب باستخدام الحاسب الآلي وطباعة بواسطة برنامج نقش خاص ، ويتم نقل معلومات التصميم والتنضيد تلقائيًا إلى وحدة التحكم عن طريق الكمبيوتر ، وتتحكم وحدة التحكم في آلة النقش لتوليد مسارات النقش على المحور X و Y و Z لاستكمال معالجة المواد المثبتة على طاولة العمل ، لتحقيق متطلبات المعالجة المختلفة للمستخدمين.

مع ميزات التكلفة المنخفضة والتشغيل البسيط والصيانة السهلة ، تعتبر ماكينة CNC CNC آلة للمبتدئين في صناعة آلات النجارة ويفضلها المستخدمون في الداخل والخارج. يقوم جهاز التوجيه الخشبي بشكل رئيسي ببعض معالجة الطائرة على اللوحة. إذا كنت تقوم فقط بالقطع المسطح على بعض الأطباق ، فإن جهاز التوجيه الخشبي CNC هذا هو بالتأكيد خيارك المثالي.

بالطبع ، إذا كانت لديك متطلبات تصنيع أخرى مثل قطع العمل ثلاثية الأبعاد ، وتصنيع سطح منحني لقطع العمل المعقدة ، فلدينا أيضًا معدات CNC مثل آلة النقش بأربعة محاور ، وآلة النقش بالمحور الدوار ، وجهاز التوجيه ATC CNC والرأس المتعدد آلة الحفر لتختار.

مواد المعالجة الرئيسية لجهاز التوجيه الخشبي باستخدام الحاسب الآلي

تستخدم آلة التوجيه CNC هذه بشكل أساسي لمعالجة الاكريليك ، لوح PVC ، لوح مزدوج اللون ، لوح خشب ، MDF ، رخام ، لوح نار ، لوح مطاطي ، زجاج ، كريستال ، إلخ.

حجم وتكوين جهاز التوجيه الخشبي باستخدام الحاسب الآلي

الأحجام الأكثر شيوعًا لآلة الخشب باستخدام الحاسب الآلي هي على النحو التالي 1300 * 2500 مم (4 * 8 بوصة) ، 1500 * 3000 مم (5 * 10 بوصة) ، 2000 * 3000 مم (6 * 10 بوصة) و 2000 * 4000 مم (6 * 12 بوصة).

(جدول التكوين)

لا يتم إصلاح حجم معالجة الجهاز ولا تكوين الجهاز. نحن نقدم خدمات حسب الطلب. وفقًا لاحتياجات المعالجة المختلفة للعملاء ، يتم تخصيص الجهاز الأنسب والأكثر فعالية من حيث التكلفة للمستخدمين.

صناعات التطبيق الرئيسية لجهاز التوجيه الخشبي باستخدام الحاسب الآلي

لا يقتصر جهاز التوجيه CNC لأعمال الخشب فقط في مجال الأعمال الخشبية ، يمكن استخدام هذه الماكينة في العديد من الصناعات الأخرى مثل صناعة الإعلان ، الصناعة الحرفية ، صناعة القوالب ، صناعة الإلكترونيات ، صناعة البناء ، صناعة الطباعة والتغليف ، صناعة الديكور ، صناعة شواهد القبور ، الكريستال صناعة المنتجات ، إلخ.

مزايا معالجة راوتر الخشب باستخدام الحاسب الآلي

أداء عالي التكلفة. يمكن تلبية متطلبات المعالجة دون ارتفاع تكاليف الشراء والتدريب. هذا النوع من آلة نقش الخشب يمكن أن يساعد المستخدمين على توفير 30٪ من تكلفة الشراء. كما يمكن استخدامه كآلة قطع الخشب باستخدام الحاسب الآلي ، خاصة بالنسبة لقطع mdf ، قطع الخشب.

مجموعة واسعة من التطبيقات. يمكن استخدام آلة الخشب CNC على نطاق واسع في صناعة الإعلان ، الصناعة الحرفية ، صناعة العفن ، صناعة الإلكترونيات ، صناعة البناء ، صناعة الطباعة والتغليف ، صناعة الخشب ، صناعة الديكور ، صناعة شواهد القبور ، إلخ.

مواد معالجة واسعة النطاق. يمكن لآلة الخشب CNC أن تلبي معالجة معظم المواد غير المعدنية مثل الأكريليك ، لوح PVC ، لوح الكركديه ، لوح ثنائي اللون ، لوح خشبي ، لوح كثيف ، رخام ، لوح نار ، لوح مطاطي ، زجاج ، كريستال.

درجة عالية من الأتمتة. مقارنةً بطرق المعالجة التقليدية في الماضي ، تمت زيادة كفاءة معالجة جهاز التوجيه الخشبي باستخدام الحاسب الآلي بنسبة 50٪ ، مما يحقق هوامش ربح أكبر للمستخدمين.

.jpg)

عدد كهربائية

عدد كهربائية

.jpeg) ادوات اسطمبات

ادوات اسطمبات

ادوات قياس

ادوات قياس

ادوات تخزين

ادوات تخزين

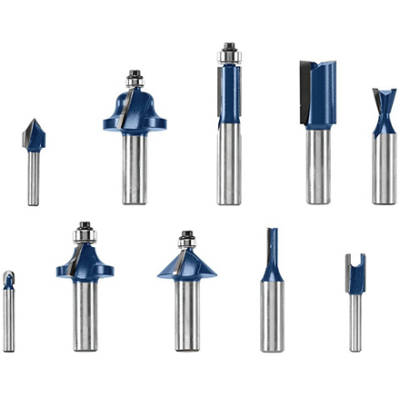

عدد راوتر اخشاب

عدد راوتر اخشاب

.png)

.jfif)