.jfif)

.jfif)

كيفية اختيار نوع السلك لماكينه الواير؟

خصائص سلك EDM

قوة الشد

قوة الشد هي أقصى قدرة على التحمل تُمنح للمادة بناءً على قدرتها على مقاومة التمدد والكسر. يتم تحديده من خلال الحد الأقصى للحمل بالجنيه لكل بوصة مربعة مقسومًا على مساحة المقطع العرضي للسلك. يوفر سلك EDM عالي الشد استقامة أفضل للحواف ، وبالتالي فهو خيار جيد للأجزاء أحادية التمرير والأسلاك ذات القطر الصغير والدقيق لتقليل تكسر الأسلاك. يعد قطع الأسلاك في الأجزاء الطويلة تطبيقًا آخر يتطلب استقامة جيدة ومقاومة لكسر الأسلاك. يعتبر السلك عالي الشد مفيدًا أيضًا في عمليات القطع الخالي من الدسم ، مما يساعد في الاستقامة الجزئية والدقة الهندسية.

مقاومة الكسر

لا يوجد مؤشر حقيقي أو "تصنيف" لمقاومة الكسر ، لذلك من الأفضل وصف مقاومة الكسر لسلك EDM بأنها متانة أو مرونة السلك. إنها قدرة السلك على مقاومة تأثيرات البيئة الديناميكية بشكل لا يصدق لفجوة الشرارة.

التوصيل

هذا هو مقياس قدرة المادة على حمل التيار الكهربائي. في EDM ، كلما زادت موصلية السلك ، زادت الطاقة التي يمكن توصيلها إلى قطعة العمل. نظرًا لأن الموصلية الأعلى تكون أكثر كفاءة ، فإن زيادة سرعات القطع هي النتائج المعتادة.

درجة حرارة التبخير

ستثبت درجة حرارة الانصهار / التبخير المنخفضة للسلك أنها الأفضل لقابلية الانصهار. نريد أن يتبخر سطح السلك ، ليتحول بسرعة إلى غازات ، بدلاً من تلويث الفجوة بـ "رقاقات" مقواة. جميع الرقائق لها كتلة وبالتالي "تشغل مساحة". فجوة الشرارة صغيرة بما يكفي بالفعل ولا نحتاج إلى "قطع من الأشياء" تطفو بداخلها. عند الاستخدام لفترات أطول (خشونة) ، سيحدث الذوبان. على الرغم من أن الانصهار ينتج رقاقات ، فإن سبائك الأقطاب الكهربائية منخفضة الحرارة (المغلفة بالزنك) ستنتج ثقوبًا أكبر على سطح السلك لحمل المزيد من المياه والملوثات بعيدًا عن الفجوة ، مما يساعد على التنظيف. وبالتالي ، فإن الأسلاك المولي والتنغستن ، مع درجات حرارة عالية للذوبان / التبخر تنخفض ببطء وتتدفق بشكل سيئ ، ولكنها مرضية لعمليات القطع المقشودة حيث لا تمثل السرعة مشكلة ولكن الاستقامة الجزئية والهندسة الواضحة.

صلابة

غالبًا ما يتم الخلط بين مصطلح الصلابة وقوة الشد. تشير صلابة السلك أو مزاجه إلى ليونة السلك ، أو قدرته على الخضوع للاستطالة. في هذه الفئة ، تسمى أسلاك EDM لينة أو صلبة. في الآلات ذات التوجيه المغلق ، سوف يخيط السلك الصلب بشكل أفضل من السلك الأكثر ليونة ، لكن السلك اللين سوف يتم تقطيعه بشكل أفضل. سيوفر السلك الصلب أيضًا أفضل موثوقية في خيوط المعالجة التلقائية.

أنواع الأسلاك EDM

سلك نحاس

كان أول سلك يستخدم للسلك EDM هو النحاس. إن التوافر والموصلية العالية (100٪ IACS) جعلته خيارًا منطقيًا لقطب EDM في ذلك الوقت ، ولكن مع زيادة قوة المولدات ، كشفت سرعة القطع المحدودة للنحاس وقوة الشد المنخفضة (34000-60.000psi) بسرعة عن قيودها. باستثناء الآلات القديمة التي تحدد استخدام الأسلاك النحاسية ، نادرًا ما يوصى باستخدام هذا السلك. في هذه الآلات ، يجب استخدام هذا السلك لقطع الأسلاك لجميع المواد لمجرد عدم وجود بديل آخر.

سلك نحاس

يُضاف عنصر الزنك إلى النحاس لإنتاج سلك EDM النحاسي ، وهو أكثر أسلاك EDM شيوعًا المستخدمة اليوم. عادةً ما تكون الأسلاك النحاسية الخاصة بـ EDM عبارة عن سبيكة تتراوح بين 63/37 (أمريكي وأوروبي) إلى 65/35 (آسيوي) ، نسبة النحاس / الزنك. يحتوي الزنك على نقطة انصهار / تبخير أقل مما يجعله مادة قطب كهربائي أفضل من النحاس ، لذلك كلما زاد الزنك في سطح سلك EDM ، كلما كان القطع أسرع. ومع ذلك ، تنشأ صعوبات التصنيع عندما يقترب حجم الزنك من 40٪ ويتغير هيكله البلوري إلى طور جاما ، مما يتسبب في أن يصبح السلك هشًا للغاية ويصعب سحبه. ومع ذلك ، يوجد سلكان يتم إنتاجهما بمحتوى 60/40 Cu / Zn لسرعات قطع أسرع. تتراوح قوة شد الأسلاك النحاسية بين 54000 و 173000 رطل / بوصة مربعة ، اعتمادًا على تكوين السبيكة ومزاجها. عادة ما تكون الأسلاك النحاسية ذات لون نحاسي لامع. تعتبر الأسلاك النحاسية ذات اللون الباهت غير اللامع أو التي بها بقع أو تغير في اللون مؤشرات على الأكسدة أو التلوث. الأسلاك النحاسية عبارة عن أسلاك خدمات جيدة وشاملة يمكن استخدامها بواسطة معظم الآلات الحديثة. القطع الاقتصادي لأدوات الفولاذ ومعظم المعادن ممكن باستخدام الأسلاك النحاسية العادية. متوفر في صلابة (استطالة) في نطاقات من <2٪ إلى أكثر من 30٪. الأسلاك ذات النسب المنخفضة من الاستطالة سوف تتدلى بشكل موثوق ولكنها محدودة في القدرة على التناقص. على العكس من ذلك ، يمكن أن تتقلص الأسلاك ذات الاستطالة العالية إلى 45 درجة ولكن مع انخفاض موثوقية الخيوط.

سلك مطلي

أسلاك EDM المطلية عبارة عن أسلاك لها طبقة رقيقة جدًا (2-3 ميكرومتر) من الزنك النقي المطبق على قلب نحاسي أو نحاسي. الجلفنة الكهربائية هي الطريقة الأكثر دقة للتطبيق ، وترسيب الزنك النقي ، والذرة بذرة على جسم السلك ، مما يضمن سماكة موحدة وتوحيد السطح. الغمس الساخن طريقة أخرى لطلاء السلك. إنها طريقة طلاء أسرع وأقل دقة وعادة ما تكون هذه الأسلاك أقل تكلفة. هذه الأسلاك متوفرة بقوة شد من 61000 إلى 130.0

.jpg)

عدد كهربائية

عدد كهربائية

.jpeg) ادوات اسطمبات

ادوات اسطمبات

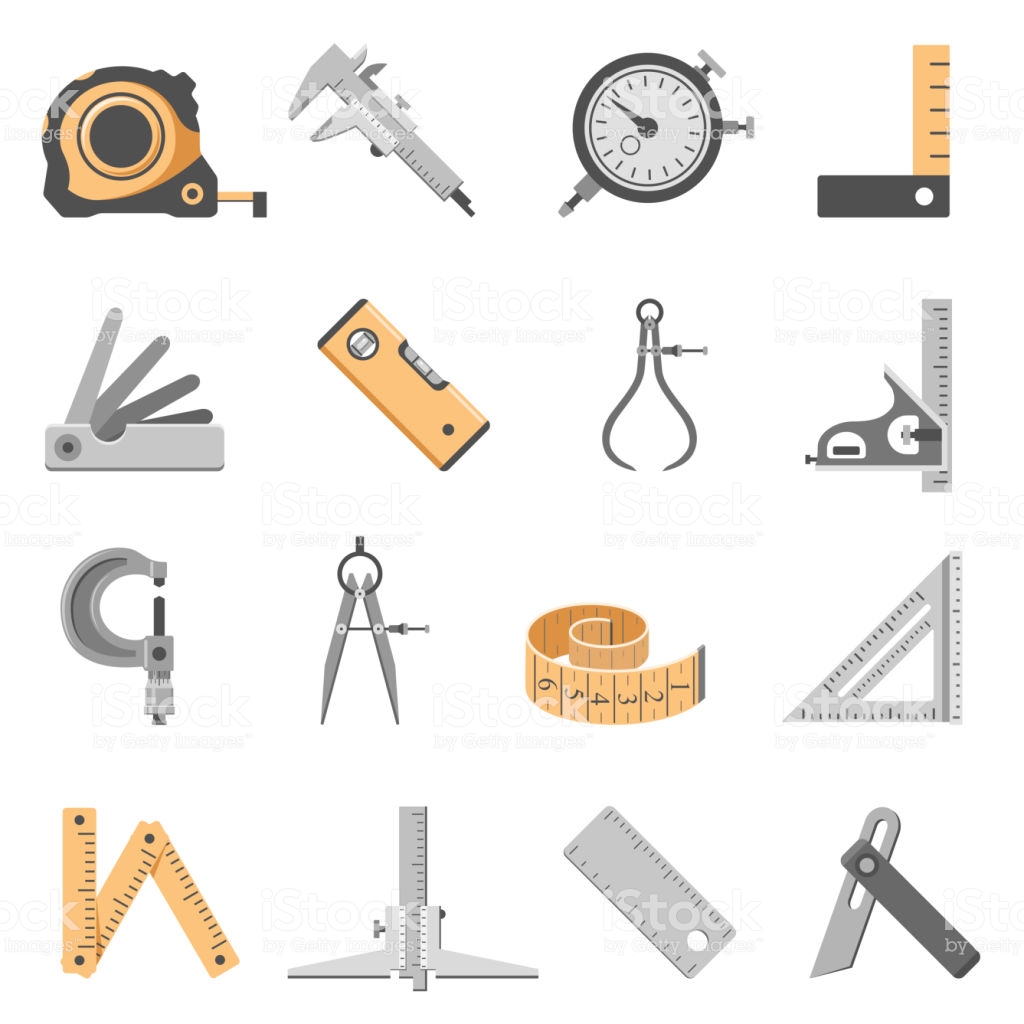

ادوات قياس

ادوات قياس

ادوات تخزين

ادوات تخزين

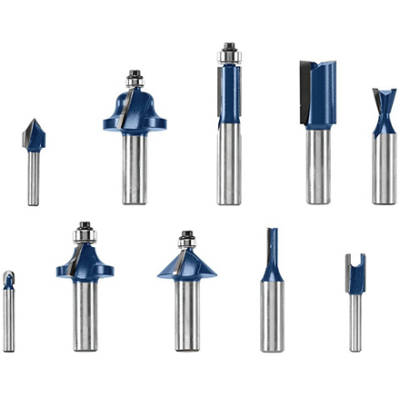

عدد راوتر اخشاب

عدد راوتر اخشاب

.png)

.jfif)