.jfif)

كيف تشتري فريزة سي ان سي؟

كيفية شراء آلة CNC

1. استشر: سوف نوصيك بآلات الطحن CNC الأكثر ملاءمة لك بعد إبلاغك بمتطلباتك ، مثل المواد التي تريد نحتها ، والحد الأقصى لحجم المادة (الطول × العرض × السماكة).

2. عرض الأسعار: سوف نقدم لك عرض أسعار مفصلاً وفقًا لآلات CNC التي تمت استشارتها ، بجودة عالية وسعر آلة CNC بأسعار معقولة.

3. تقييم العملية: يقوم كلا الجانبين بتقييم ومناقشة جميع تفاصيل الأمر بعناية لاستبعاد أي سوء فهم.

4. تقديم الطلب: إذا لم يكن هناك شك ، سوف نرسل لك PI (الفاتورة الأولية) ، ثم سنوقع عقدًا معك.

5. الإنتاج: سنقوم بترتيب الإنتاج بمجرد استلام عقد البيع الموقّع والإيداع. سيتم تحديث آخر الأخبار حول الإنتاج وإبلاغ المشتري أثناء الإنتاج.

6. التفتيش: ستكون إجراءات الإنتاج بأكملها تحت التفتيش المنتظم ورقابة صارمة على الجودة. سيتم اختبار آلة CNC الكاملة للتأكد من أنها يمكن أن تعمل جيدًا قبل الخروج من المصنع.

7. التسليم: سوف نقوم بترتيب التسليم على النحو الوارد في العقد بعد تأكيد المشتري.

8. التخليص الجمركي: سنقوم بتوريد وتسليم جميع وثائق الشحن اللازمة للمشتري وضمان التخليص الجمركي السلس.

9. الدعم والخدمة: سوف نقدم دعمًا فنيًا محترفًا وخدمة آلة CNC عن طريق الهاتف والبريد الإلكتروني و Skype و WhatsApp على مدار الساعة.

.jpg)

عدد كهربائية

عدد كهربائية

.jpeg) ادوات اسطمبات

ادوات اسطمبات

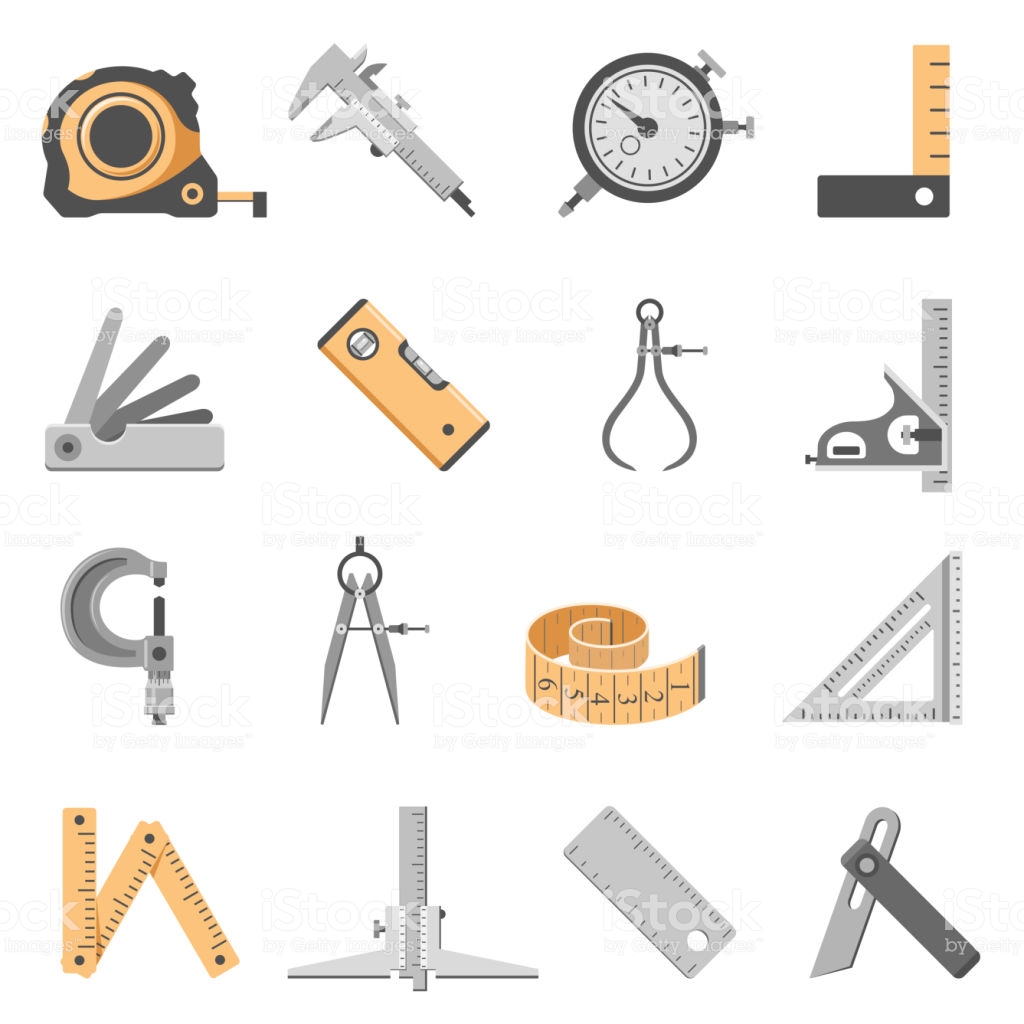

ادوات قياس

ادوات قياس

ادوات تخزين

ادوات تخزين

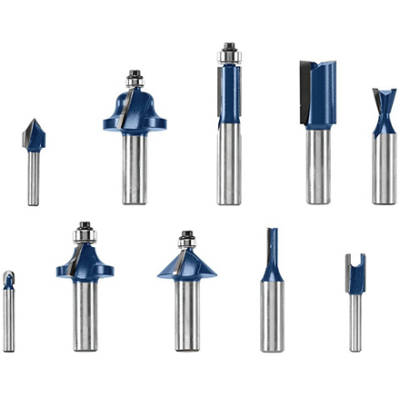

عدد راوتر اخشاب

عدد راوتر اخشاب

.png)

.jfif)