.jfif)

كيف نختار سرعة الليزر في الحديد؟

كيفية اختيار أفضل سرعة لقاطع الليزر الصلب؟

سوف تؤثر قوة الليزر على سرعة قطع الليزر الفولاذية. سوف تؤثر سرعة القطع على جودة القطع. في حالة وجود قوة ليزر معينة ، فإن السرعة أو البطء جدًا ستؤثر على التسطيح السطحي لمادة القطع.

إذا كانت سرعة القطع سريعة جدًا:

1. شعاع الليزر والمواد على اتصال مع بعضها البعض في وقت قصير ، مما قد يؤدي إلى عدم القدرة على القطع.

يمكن قطع بعض المناطق ، ولكن لا يمكن قطع بعض المناطق.

3.قسم قطع كامل.

4.لا يمكن قطع اللوحة في الوقت المناسب. يُظهر قسم القطع طريقًا قطريًا مائلًا ، وينتج الجزء السفلي بقع ذوبان.

إذا كانت سرعة القطع بطيئة جدًا:

1.وقت التفاعل بين المادة والليزر طويل جدًا ، مما يؤدي إلى ذوبان اللوحة بشكل مفرط وقسم القطع خشن.

2. يصبح الشق أوسع. إنه يسبب حرقًا زائدًا في الزوايا المستديرة الأصغر أو الزوايا الحادة ، ولا يمكن الحصول على تأثير القطع المثالي.

3. كفاءة القطع منخفضة ، مما يؤثر على القدرة الإنتاجية.طريقة الحكم لسرعة القطع.

كيفية الحكم على سرعة القطع المناسبة?

1. سرعة القطع معقولة: الشرارات منتشرة من الأعلى إلى الأسفل ، سطح القطع أملس ، ولا يوجد خبث في الجزء السفلي ؛

2. سرعة القطع سريعة للغاية: تميل شرارة القطع ؛

3. سرعة القطع بطيئة للغاية: يتم تكثيف شرارات القطع معًا ، ولا تنتشر.

كمصنع محترف لآلة القطع بليزر الألياف ، طور جهاز ليزر خاص بالعلامة التجارية. قوة الليزر من 750w إلى 8kw.

1. هيكل تبريد الطبقات. يمكن أن يتجنب هذا التكثف الناتج عن ارتفاع درجة الحرارة والرطوبة العالية ، والحفاظ على درجة حرارة ثابتة عند 23 ℃.

2. نوعية جيدة شعاع BPP. يتم استيراد جميع الأجهزة الأساسية وتنفيذ عملية الربط الممتاز للألياف البصرية.

3. كفاءة تحويل كهربائية بصرية عالية ، يمكن أن تصل إلى 35 ٪.

.jpg)

عدد كهربائية

عدد كهربائية

.jpeg) ادوات اسطمبات

ادوات اسطمبات

ادوات قياس

ادوات قياس

ادوات تخزين

ادوات تخزين

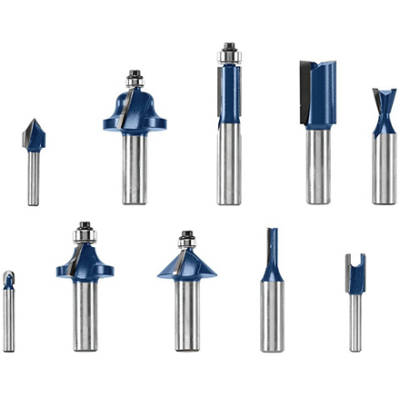

عدد راوتر اخشاب

عدد راوتر اخشاب

.png)

.jfif)